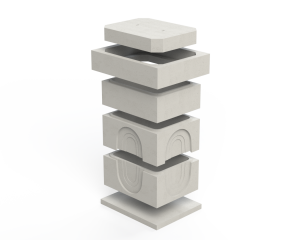

Sectional Junction Box

Machine made reinforced concrete sections in accordance with BS.5911 part 2, with mating rebated edges which can be easily assembled to various depths. Provided with un-reinforced knock-out sections to accommodate pipe entry where required. There is a 50mm thick concrete slab for the base and a range of lid options.

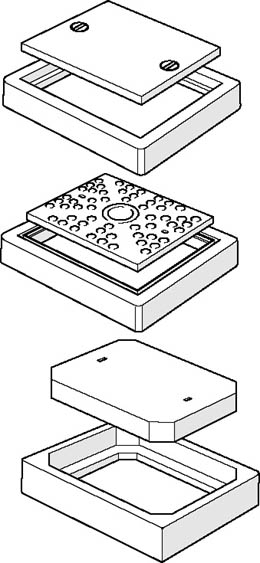

Standard Lid for Sectional Junction Box

Approximate weight: 120kg.

A 65mm thick reinforced concrete lid with recessed galvanized handles is fitted into a 100mm thick concrete surround locating on the junction box extension. Suitable for pedestrian areas, not for heavy traffic.

Pressed Steel Lid for Sectional Junction Box

Approximate weight: 60kg.

Steel frame is cast into the reinforced concrete surround effectively 50mm thick and fitted with 17 tonne GVW pressed galvanized steel lid.

Screwed down Steel Lid for Sectional Junction Box

Approximate weight: 60kg.

Plastic frame is cast into the reinforced concrete surround effectively 50mm thick and fitted with 10 tonne GVW pressed galvanized steel screw down lid.

Heavy Duty Lid for Sectional Junction Box

Approximate weight: 160kg.

125mm thick reinforced concrete lid fits into a 180mm deep concrete surround locating on the junction box extension. Galvanized steel lifting keys are available for use with these lids.

Surface water inlet lid with silt box and gravel tray

Used as a surface inlet with optional silt trap box and stones box to hold gravel above grating.

Technical Specification

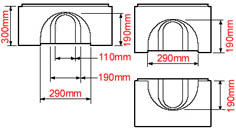

- Internal dimensions: 610mm x 460mm

- Maximum size through knock-out web: 290mm

- Modules: 150mm (45kg), 225mm (68kg), and 300mm (90kg)

- Approximate weight with no lid: 230kg